Conductivity refers to the ability of a solution to allow electricity to pass through it. Measuring conductivity has multiple applications ranging from testing water quality for agriculture to detecting leaks in industrial heat exchangers. A conductivity meter helps measure the level of conductivity in a solution. However, these meters need careful calibration to ensure that they can take readings accurately.

Here we will cover some essential aspects of Conductivity Meter Calibration Logs.

- What are some of the critical details captured in Conductivity Meter Calibration Logs?

- Why are these Logs vital to numerous industrial processes?

- How can Fielda help organizations use Conductivity Meter Calibration Logs more effectively?

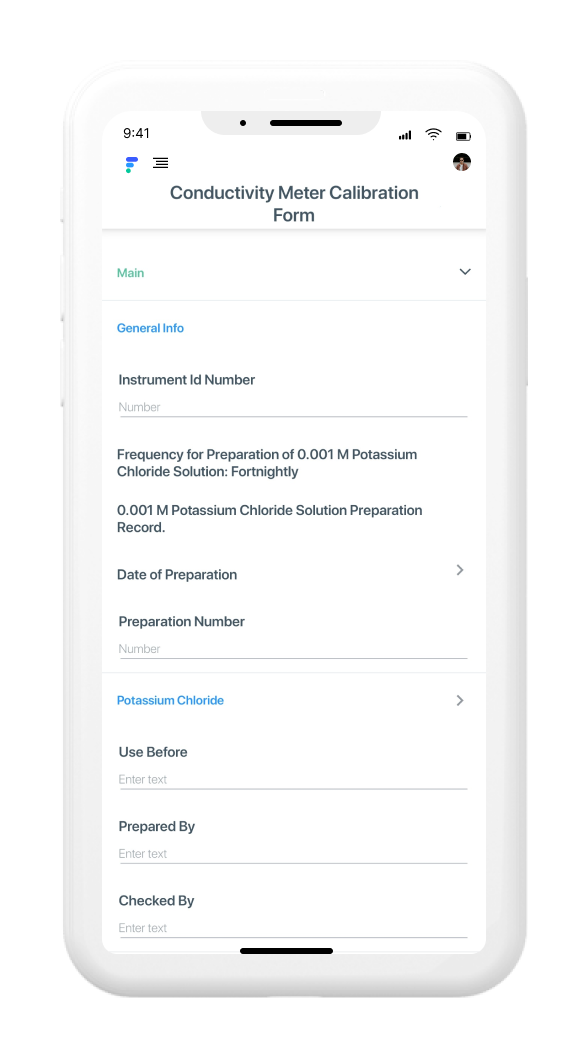

Key details included: Conductivity Meter Calibration is often done using standard solutions, and the meter readings are adjusted to the known lessons of the answers. The calibration log contains details such as the standards being used, the weight of the resolution, the dilution level, acceptance criteria and tolerance level, the temperature at which readings are taken, and the conductivity readings before and after calibration. These forms also record the calibration data, the last calibration done, and the next due date. The log also includes the conductivity meter, make, model, ID number, and frequency of use.

Why are these logs vital: Conductivity measures help organizations in diverse fields access the conductivity of solutions and derive conclusions regarding their quality and suitability for specific purposes. This makes conductivity calibration a vital process in ensuring accurate readings and interpretations. Conductivity readings are impacted by factors including temperature, container material in which the solution is stored, level of contamination, and presence of minerals. That’s why Conductivity Meter Calibration Logs are used to ensure the calibration is done in carefully managed environments and using strict protocols and SOPs.

Benefits of Fielda’s Conductivity Meter Calibration Log: Fielda helps lab personnel perform conductivity meter calibrations faster, create, edit and update logs using Fielda’s custom forms feature. Its intuitive screens and menus make data capture convenient and efficient for calibration technicians. Companies can also track calibration history, review calibration readings across devices, and set triggers for future calibration dates.

Design: Create and customize conductivity meter calibration logs to suit your organization’s specific requirements and workflow

Calibrate: Ensure accuracy of conductivity readings for all your business applications through meticulously managed calibration protocols

Optimize: Enhance operational efficiency and lower costs through informed planning, and decision making

About Fielda: Fielda helps companies manage and maintain their assets and gain real-time oversight of all tasks, workflows, and projects to improve operational efficiency, enhance team productivity and impact the bottom line. Whether it’s installations, inspections, repairs, replacement of parts, servicing and maintenance, or routine audits, with Fielda’s mobile data collection, GIS-enabled technology, automated and custom workflows, and analytics, you can eliminate errors, enhance response time, ease workflow bottlenecks, and simplify your field operations.