Pole inspections and maintenance are always a big challenge for many electric and telecom companies. Usually, this job is outsourced to a subcontractor & they audit every pole with a rating across multiple categories.

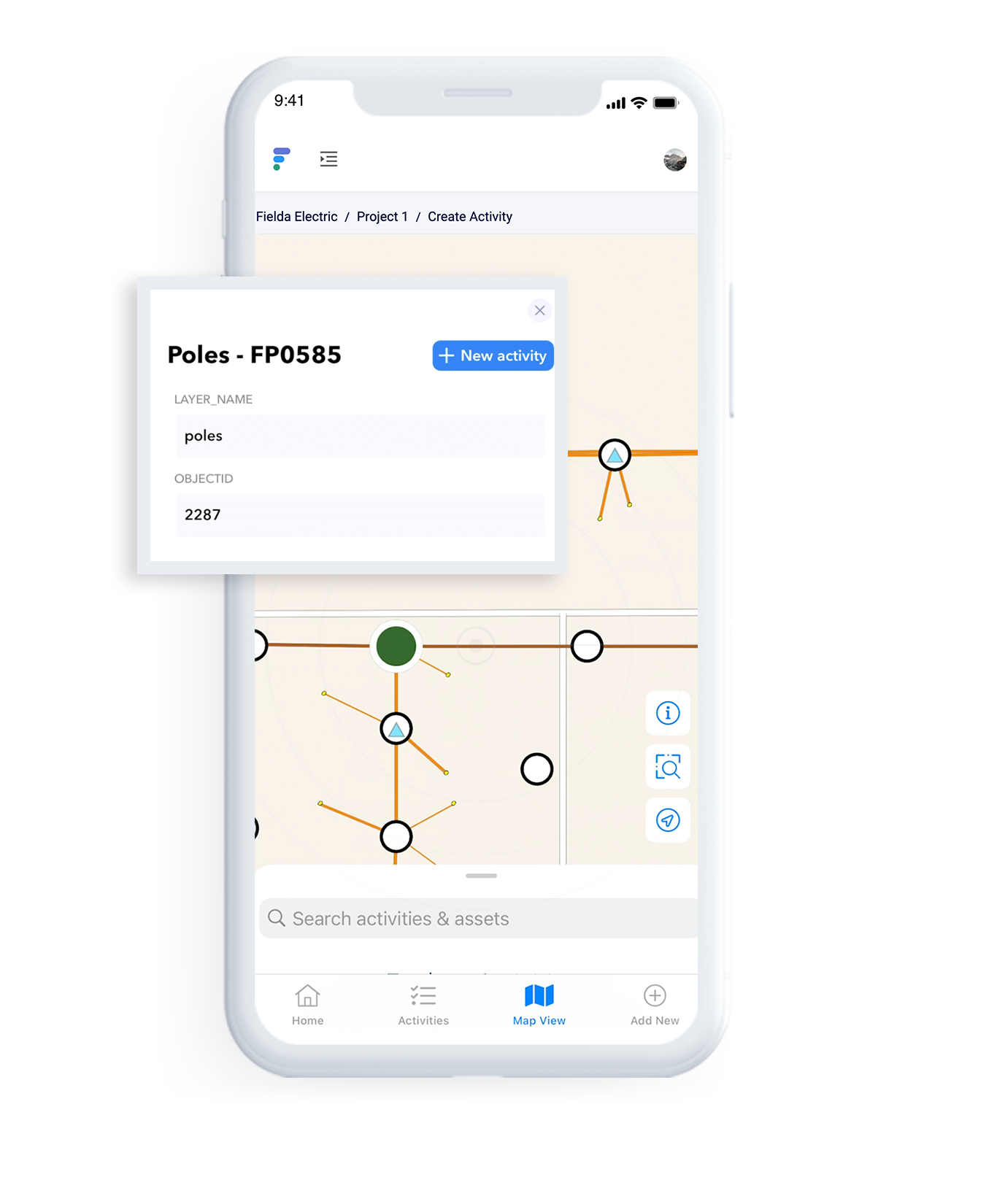

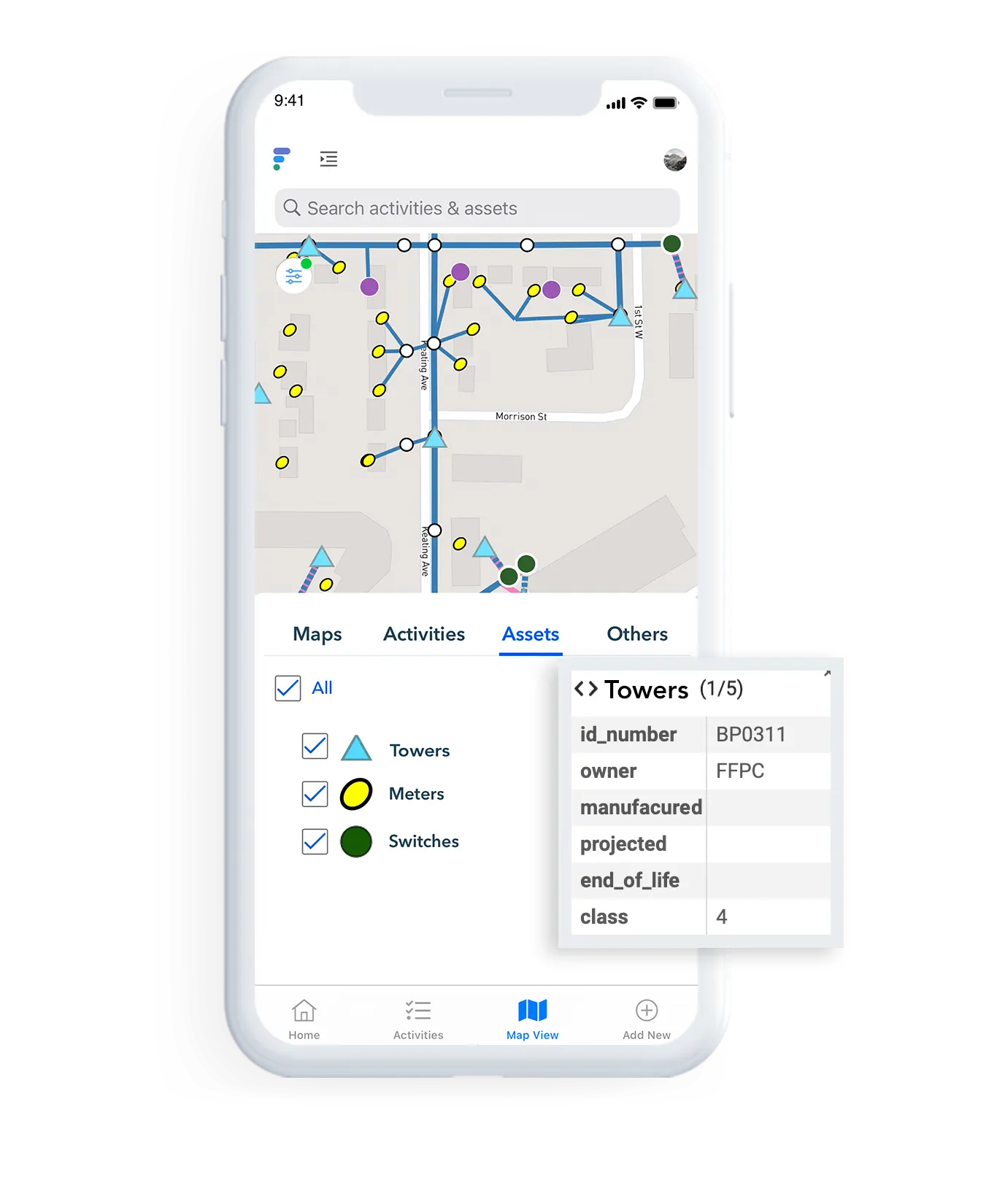

You can broadly classify the pole inspections into routine and non-routine. Routine or regular pole inspections and maintenance can prevent accidents. Using Fielda, you can track the condition of any poles (concrete or wood). In addition, a pole inspector can locate problem areas and fix them before they become hazardous.

While there are many aspects to investigate, the pole inspection checklist should consist of — but not be limited to

Various devices for detecting decay and defects are available, but they all have limitations to some degree. A non-routine inspection happens only when the pole is damaged due to a natural or an unnatural disaster.

How do a Pole inspections checklist app benefit you?