Backflow Devices help ensure the proper water pressure in a water supply system so that water always flows forward. Frequent inspections are needed so that these devices function correctly and consistently. Here we will review a few critical points about Water backflow test.

- What do Backflow Device Test Reports usually record?

- What makes these reports so crucial to the health and safety of users?

- How is Fielda geared to manage Backflow Device Test Reports more effectively?

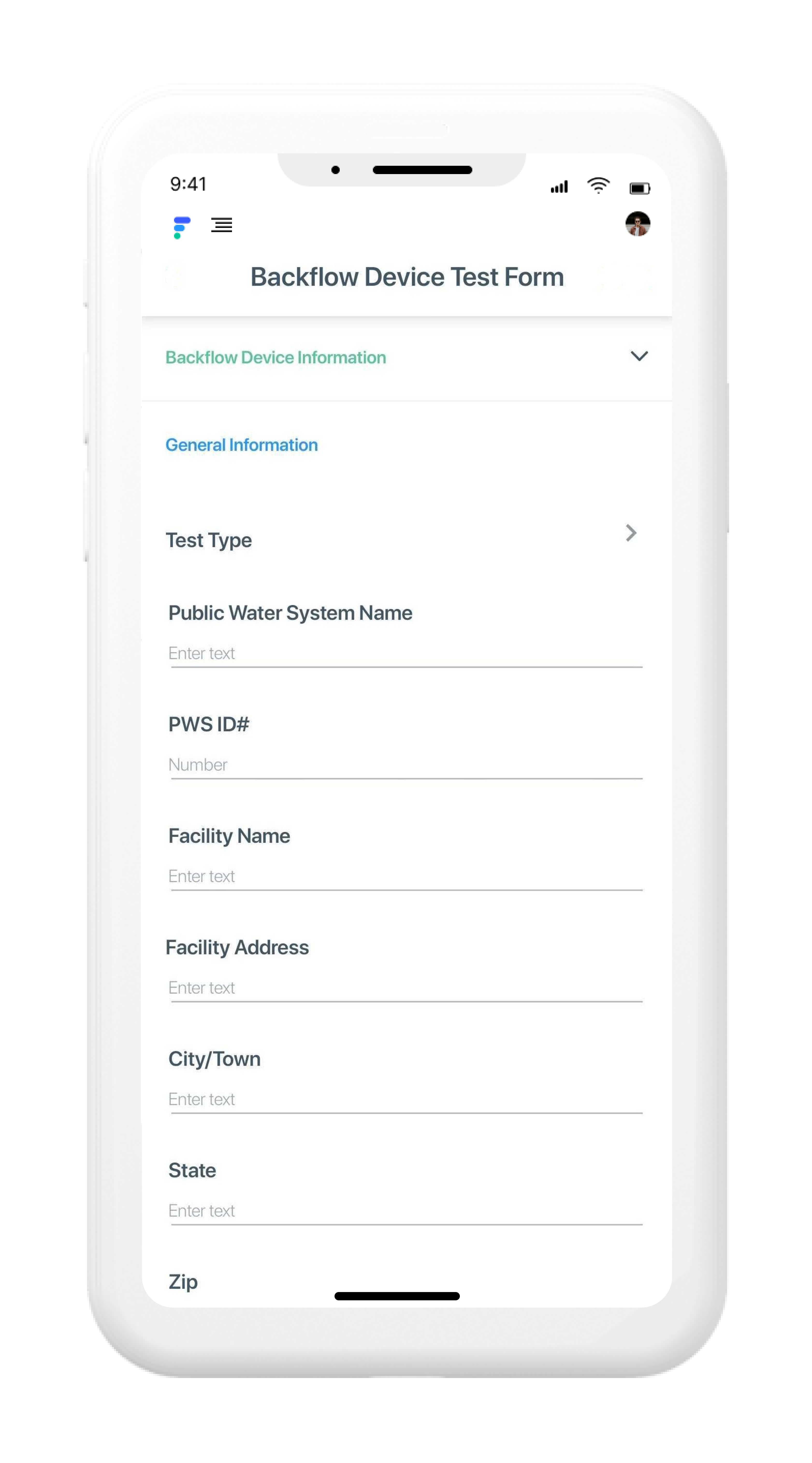

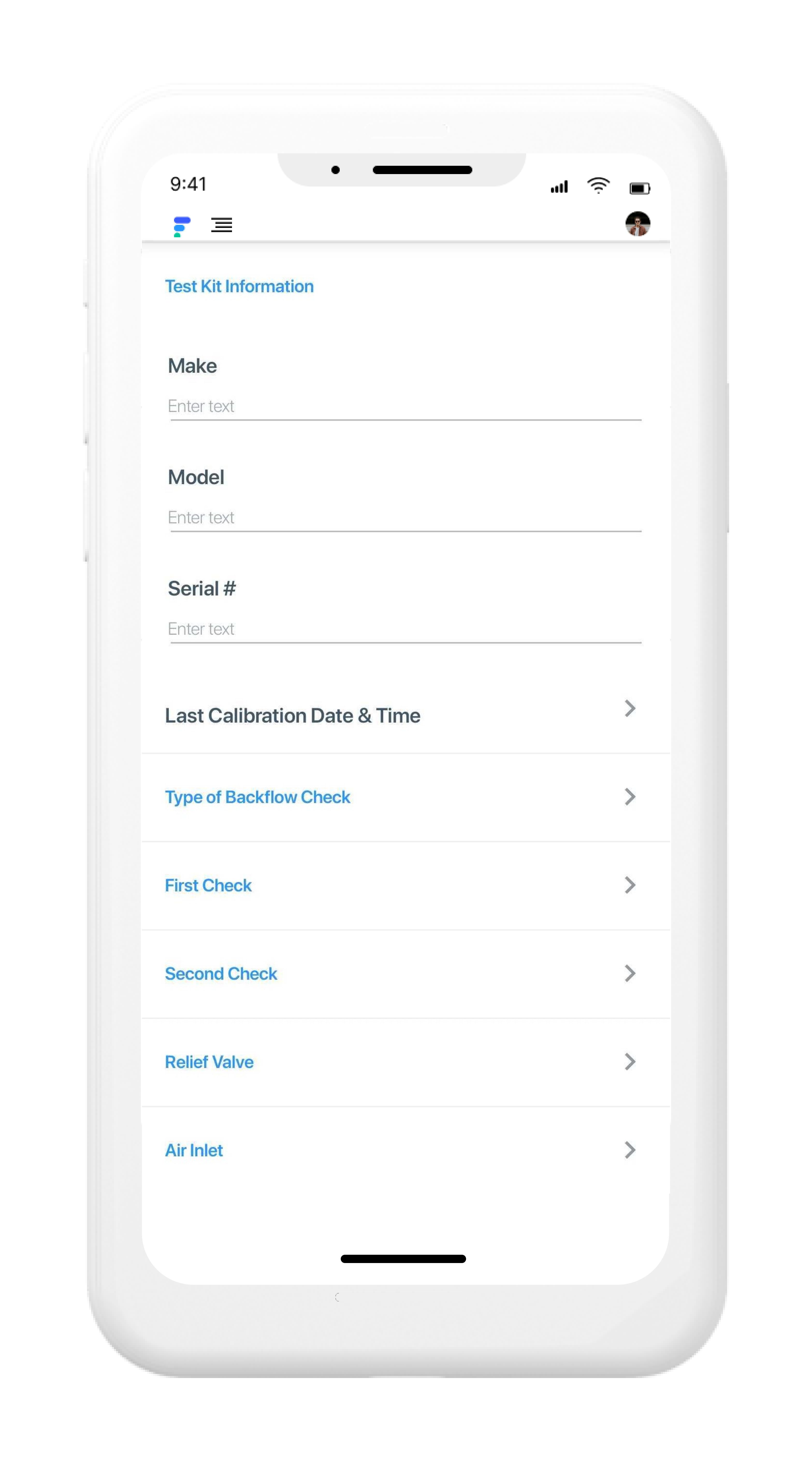

What do Backflow Device Test Reports include: During Backflow Device Tests, inspectors document details such as the size, make, serial number, and manufacturer of the device. They record their observations on the condition of the check valves and the differential pressure relief valves. They also check the valve assemblies shut off valve and pressure vacuum breaker. Inspectors add details, including the water pressure readings, pressure changes during tests conducted, the water meter readings, meter details, etc. Many forms also include information about the test kit used and the inspector’s notes about repairs needed, status before and after restoration, etc.

Why are these readings important: Whether they are used in irrigation systems for cultivation or home water supply, Backflow Devices ensure that water never flows backward. Water pressure can sometimes change because of damaged pipelines, leaks, or faulty water pumps. This can cause water to flow backward and become contaminated by mixing with pesticides and fertilizers, chlorine from swimming pools, and sewage or drainage water. This can have severe implications for the health of water consumers. It can also result in high costs of repairs, temporarily disrupt water supply, and result in violations of health and safety compliances. Backflow Device Test Reports help assess and document the condition of these vital devices and ensure necessary corrective action when needed.

How does Fielda streamline Backflow Device Test Reports: Water companies need to inspect, maintain and manage thousands of backflow devices across varying topography. Fielda’s GIS capability helps companies accurately map, visualize and manage these assets efficiently. Reports can be submitted, checked, digitally signed, and consolidated effortlessly. Fielda also helps build suitable workflows so that certified inspectors, maintenance teams, and management staff can access, review and act on field data captured in real-time. Inspectors can also seamlessly capture and submit supporting evidence documents, photos, and videos via their mobile devices.

Adapt: Design Backflow Device Test Reports to suit regulatory, organizational, and team-specific requirements for optimum data capture

Access: Gain complete visibility of operations and instant data access via Fielda’s real-time reports

Synergize: Plan resources, field staff deployment, and task allocation for better collaboration and transparency

About Fielda: Fielda helps companies manage and maintain their assets and gain real-time oversight of all tasks, workflows, and projects to improve operational efficiency, enhance team productivity and impact the bottom line. Whether it’s installations, inspections, repairs, replacement of parts, servicing and maintenance, or routine audits, with Fielda’s mobile data collection, GIS-enabled technology, automated and custom workflows, and analytics, you can eliminate errors, enhance response time, ease workflow bottlenecks, and simplify your field operations.