Sewage pipelines are an integral part of a city’s waste disposal systems. They help carry wastewater to sewage systems for treatment and processing. However, they can pose serious problems when clogged or damaged, usually from industrial waste, sanitary waste, plant tissue, or even food waste. Inspections help keep an eye on potential issues and ensure upkeep and maintenance. Here we will briefly discuss some highlights of the sewage pipeline inspections:

- How do inspectors conduct sewage pipeline inspections?

- What makes these sewage pipeline inspections so fundamental?

- How can Fielda enable inspectors with faster, smoother sewage pipeline inspections?

How do inspectors conduct sewage pipeline inspections: Inspectors document basic observations like pipeline ownership, size and length, and location. Then, they look for blockage and flooding, the blockage content, and structural damage such as corrosion, rust, cracks, and leaks. They check if the correct material has been used in the pipeline and inspect for ponding, channeling, evidence of erosion, unauthorized flows, tampering, etc. Inspectors audit for corrosion protection and check interior corrosion risks through wastewater temperature and velocity readings and exterior risks like soil acidity, groundwater levels, and surface loads.

What makes sewage pipeline inspection is so critical: Sewage pipelines are constantly exposed to several risks. These include physical damage, clogging, or wear and tear. The impact of poorly maintained sewage pipelines is often immediate and severe. This can cause overflow and flooding of sewage water, impacting environmental safety. They also cause severe problems for property owners and residents and can result in health and safety hazards if not handled. If not fixed early enough, problems in sewage pipelines can result in severe damage needing pipe replacements and large-scale repairs. These are not only expensive, but they also become tough to conduct without disruption to people in a locality. Regular inspections are the only way to ensure pipelines are in top condition to avoid these complications.

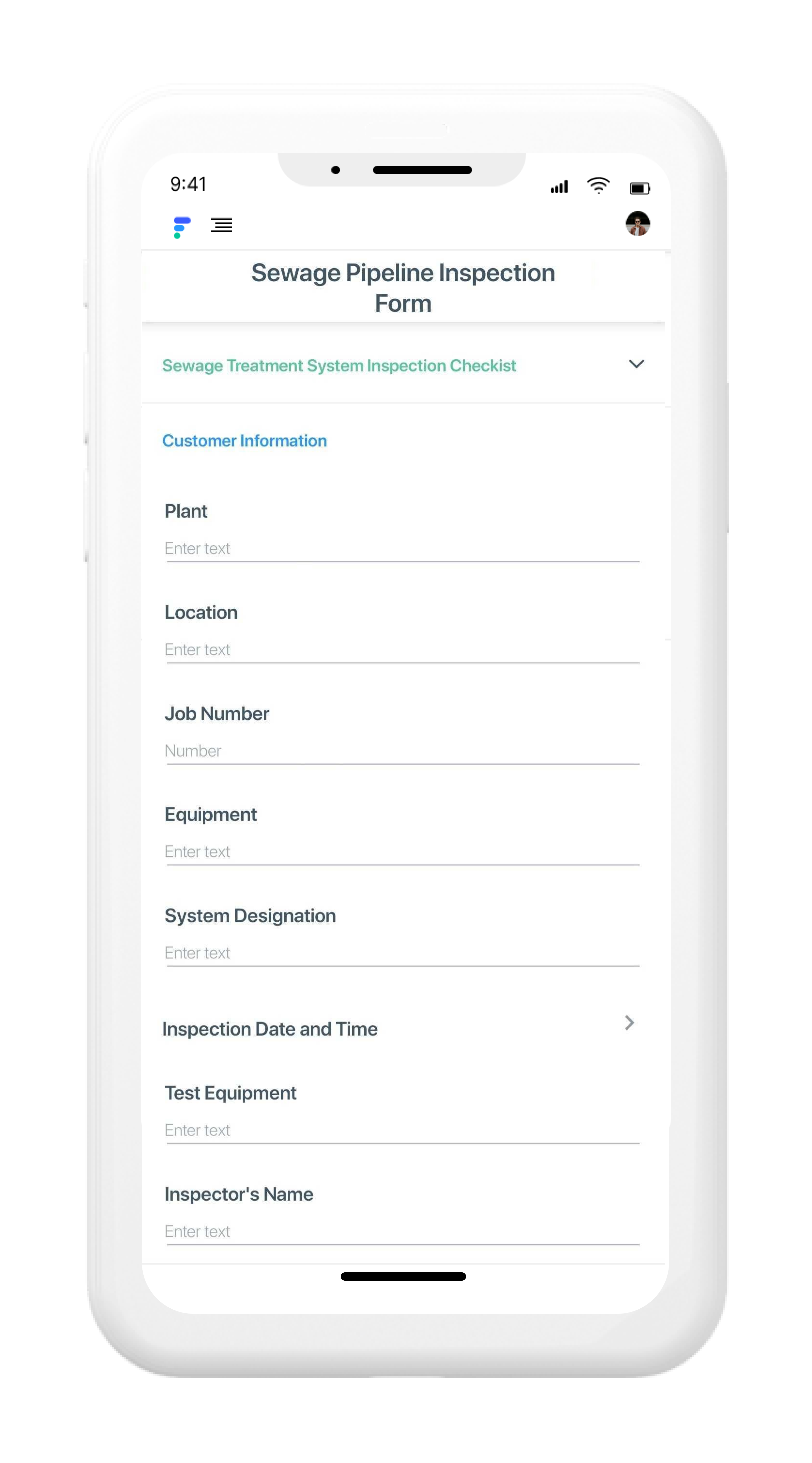

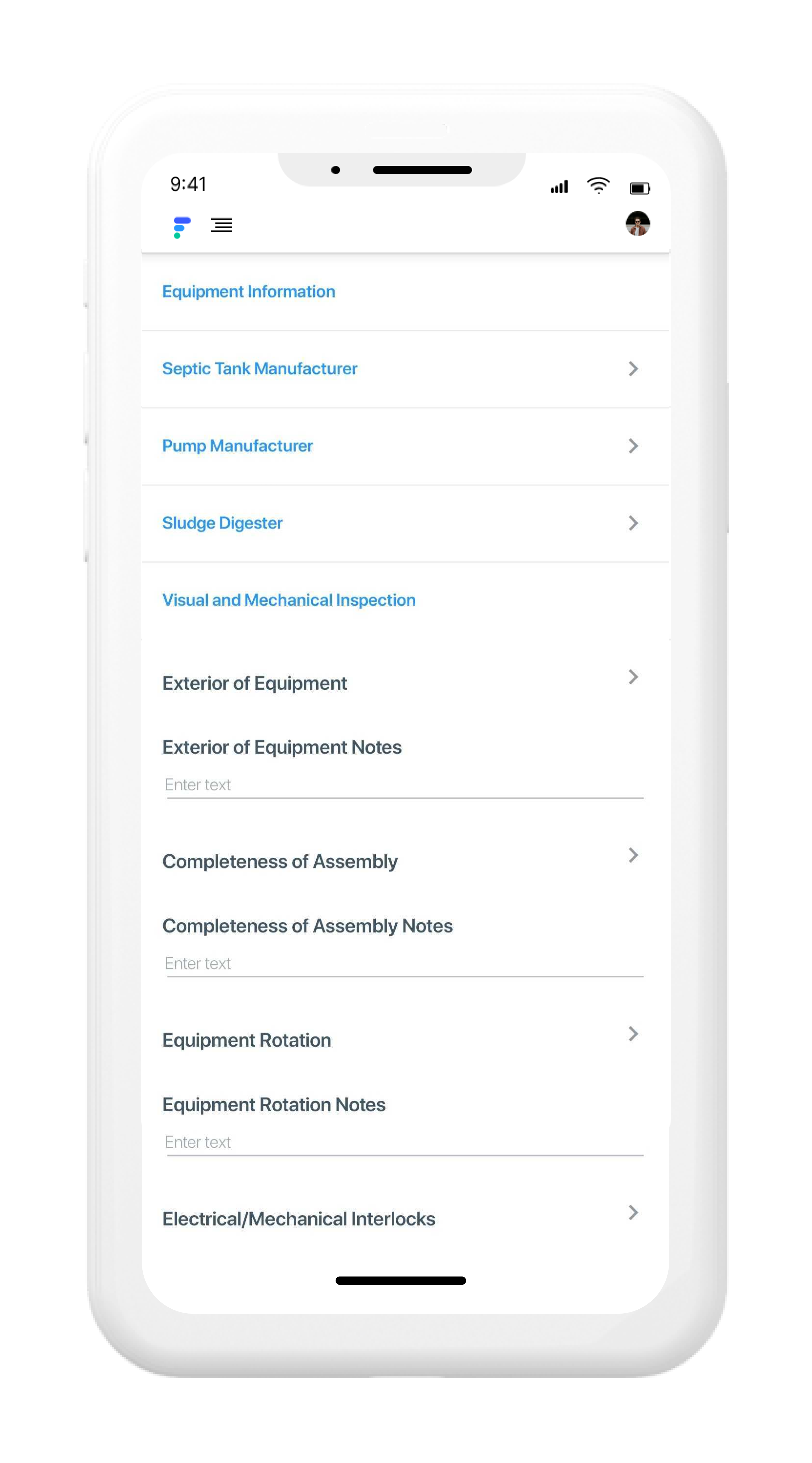

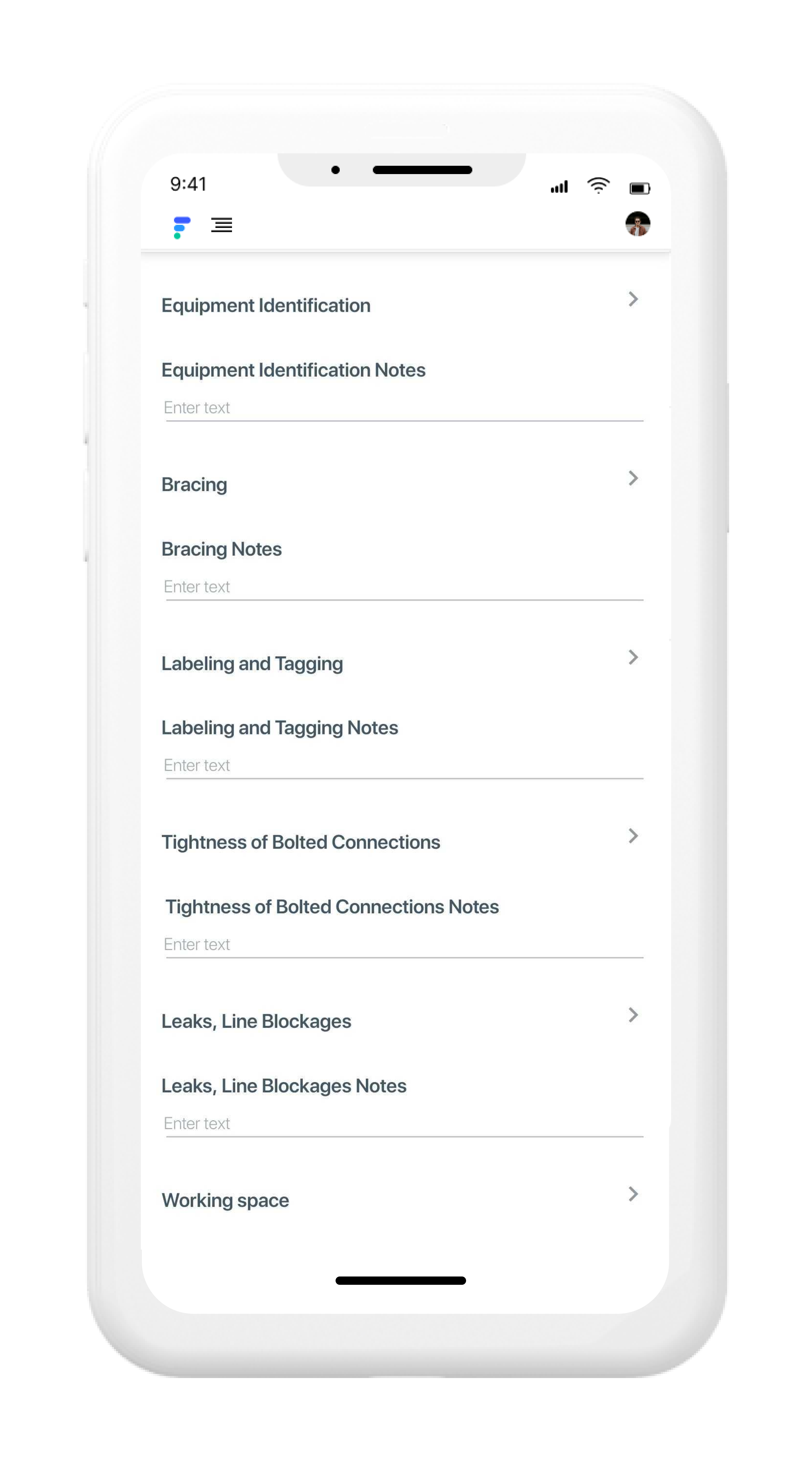

Benefits of Fielda’s Inspection Checklists: Inspectors leverage various screening techniques from visual inspection to pipeline pressure tests and even inside-pipe video cameras to capture relevant inspection data. This involves different file formats, information structures, and checklists. Fielda empowers companies to adopt a bespoke approach for other inspection teams. Data capture is uniquely designed for the inspectors’ needs and flexible to accommodate various documents and files upload. Besides editable forms, operations teams can develop a workflow to enable inspection and service teams to collaborate with transparency and efficiency. With seamless data integration Fielda empowers staff for proactive initiatives and rapid response measures.

Adapt: Build forms to suit the unique needs of inspection teams based on assets, industry standards, and processes to be followed.

Access: Enable data capture even in deep down, far off, and off-grid sites with Fielda’s offline capability.

Synergize: Achieve operational advantage through intra and inter-team collaboration for maximum productivity.

About Fielda: Fielda helps companies manage and maintain their assets and gain real-time oversight of all tasks, workflows, and projects to improve operational efficiency, enhance team productivity and impact the bottom line. Whether it’s installations, inspections, repairs, replacement of parts, servicing and maintenance, or routine audits, with Fielda’s mobile data collection, GIS-enabled technology, automated and custom workflows, and analytics, you can eliminate errors, enhance response time, ease workflow bottlenecks, and simplify your field operations.