Transformers are an essential part of the vast network used to manage electric power distribution. Therefore, their maintenance and upkeep are vital for any power distribution company to maintain a predictable and safe power supply to customers making inspections a crucial element in the operations.

This page will cover some of the critical elements of the transformer inspection checklist;

- What does a typical transformer inspection cover

- Importance of transformer inspections

- How Fielda can help eliminate errors and streamline your Transformer inspection process

What Inspections Include: Inspections are conducted daily, monthly, and annual, usually covering data on a range of items from basic ground resistance tests, grounding, and exterior checks to insulation resistance, winding configuration, and auxiliary device operation. Essential routine readings include Magnetic Oil Gauge (MOG), oil leaks check from any part of the transformer, Silica Gel color in the breather, etc.

Why Transformer Inspection is so critical: Poor maintenance can cause physical or structural damage. Fires can pose serious risks, and accidents can disrupt operations and impact health, safety, and the environment. Inspections help ensure Transformers are in top condition all the time.

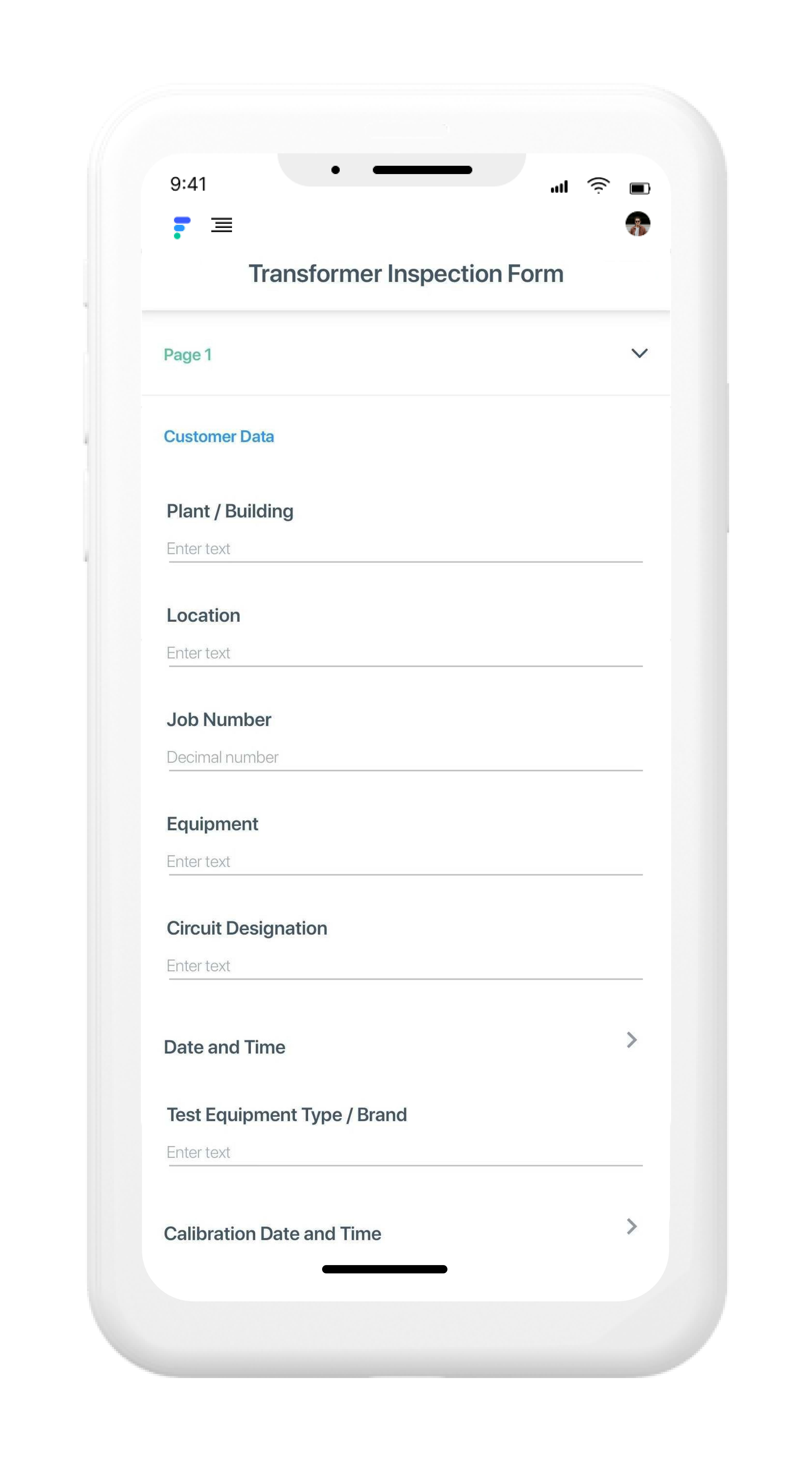

Benefits of Fielda’s Inspection Checklists: Fielda’s checklists help inspectors quickly set up, customize and use forms to gather the specific data they need daily, monthly, or annually. Inspectors can collect reliable information, capture photos, or upload evidence documents effortlessly using mobile devices or tablets. Whether maintenance or repairs are needed for the physical structure, oil level alerts, or winding configurations, transformer inspection data can seamlessly flow to other departments for action, decisions, and insights.

Enhance Data Gathering: From utility poles and cables to transformers and substations, Fielda helps you gather on-the-ground inspection data with intuitive forms and checklists.

Consolidate and Collaborate: Enhance the productivity of your engineers, inspectors, and fleet staff with improved workflow, transparency, and productivity.

Master Metrics: With data flowing in from your entire electric infrastructure network and field staff, you can stay on top of vital metrics and empower every decision with real-time intelligence.

About Fielda: Fielda helps companies manage and maintain their assets and gain real-time oversight of all tasks, workflows, and projects to improve operational efficiency, enhance team productivity and impact the bottom line. Whether it’s installations, inspections, repairs, replacement of parts, servicing and maintenance, or routine audits, with Fielda’s mobile data collection, GIS-enabled technology, automated and custom workflows, and analytics, you can eliminate errors, enhance response time, ease workflow bottlenecks, and simplify your field operations.