Electricity transmission cables in the United States span hundreds of thousands of miles. They depend on robust transmission towers to safely and reliably transmit power across this vast grid. Therefore, utility companies must conduct regular tower inspections to ensure that they are safe to operate and in optimum working condition. On this page, we’ll discuss a few highlights of tower inspection:

- What do inspectors include in typical tower inspection?

- Why are these inspections so essential to electricity supply and management companies?

- How does Fielda help inspectors conduct these tower inspections more effectively?

Transmission Tower Inspections:

Routine tower inspections involve a review of the tower structure to check for structural faults, corrosion, and damage. Inspectors check the site thoroughly to ensure there are no operational or safety threats posed to the tower from soil or adverse weather conditions. They assess the situation of paint, lighting in the building, the tightness of hardware fittings, antennae and transmission lines, etc. They also check the guy anchors, take guy tension readings and evaluate the condition of the safety climb. If there are signs of wear, damage, or defects, inspectors note these for immediate repairs or replacements as needed.

Why Tower Inspections are vital:

Unless towers are routinely inspected, they can threaten the safety of those living in the surrounding areas, cause accidents, and result in power supply disruptions. Towers are constantly exposed to the elements and can suffer severe wear and tear, posing risks to their structural integrity. In addition, towers can vary in lifespan from 15 years to 50 years depending on the extent to which they are exposed to conditions like coastal air, which is high in salt content. Tower inspections help utility companies keep a tight watch on the state of towers and take preventive and reactive measures to ensure their upkeep and increased lifespan.

How Fielda improves Tower Inspection:

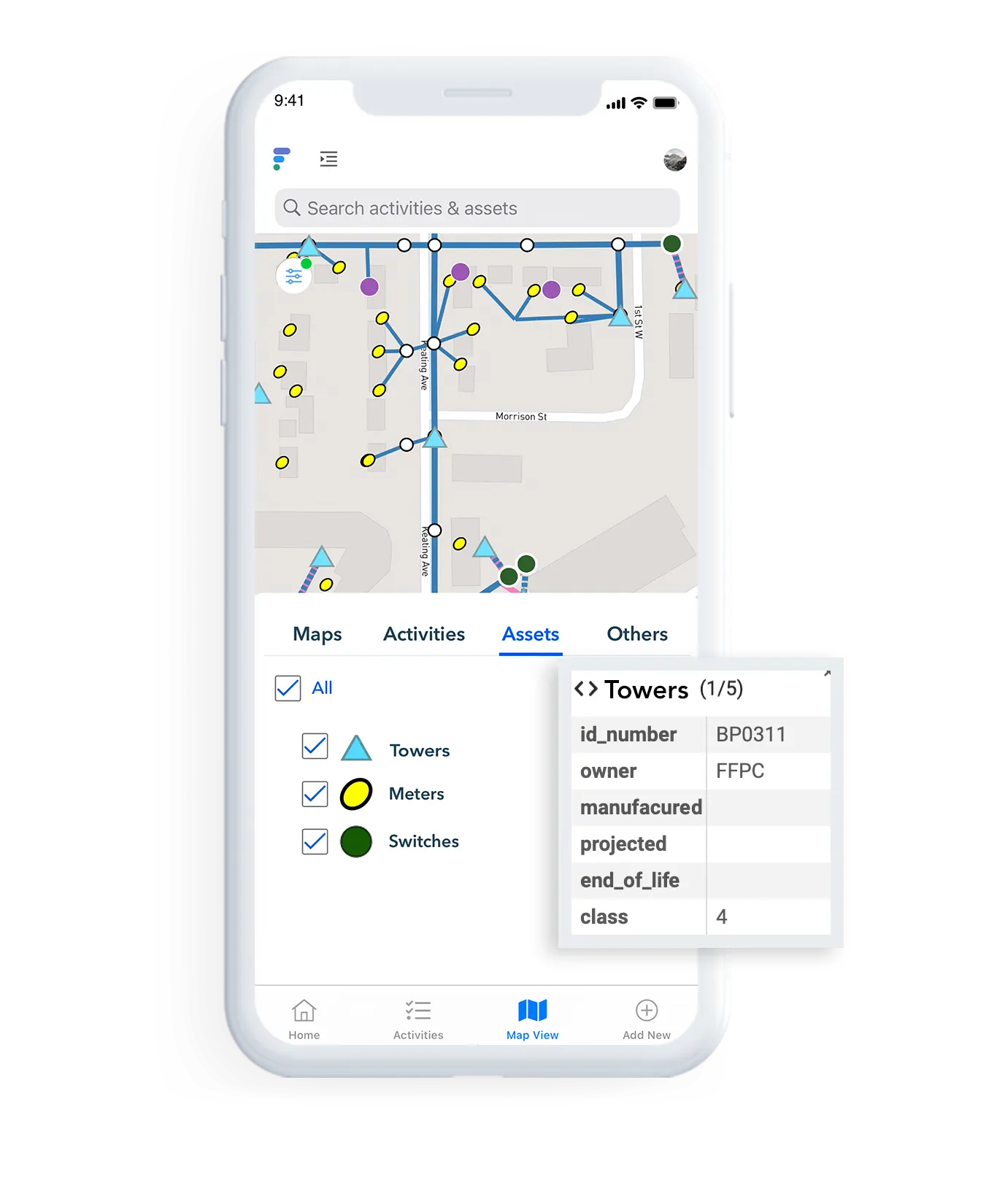

Fielda offers several powerful features to enable effortless tower inspections. Operations teams can schedule, conduct and review tower inspections allowing transparency and ease through custom workflows. In addition, inspectors can conveniently design, edit and use various digital inspection checklists for complete control of the field data-gathering process. With its advanced GIS functionality, Fielda also helps inspectors map, plot, and visualize assets accurately for tower inspection.

Inspect: Gather field data dynamically with custom digital tower inspection checklists.

Inform: Enhance collaboration through custom workflows and silo data sharing across teams.

Leverage: Gain real-time insights on inspections through advanced dashboards and metrics.

About Fielda: Fielda helps companies manage and maintain their assets and gain real-time oversight of all tasks, workflows, and projects to improve operational efficiency, enhance team productivity and impact the bottom line. Whether it’s installations, inspections, repairs, replacement of parts, servicing and maintenance, or routine audits, with Fielda’s mobile data collection, GIS-enabled technology, automated and custom workflows, and analytics, you can eliminate errors, enhance response time, ease workflow bottlenecks, and simplify your field operations.