When required, consumers rely on generators to supplement or even substitute power supply, from residential users to large industrial companies. Routine generator inspections help ensure that they provide good power quality and are reliable, especially when the load is high. Here we will examine a few crucial points about Generator Inspection Checklists.

- What is the purpose of a Generator Inspection Checklist, and what does it usually cover?

- What makes them so essential for the proper maintenance of generators?

- How does Fielda help maintenance staff effectively manage Generator Inspection Checklists?

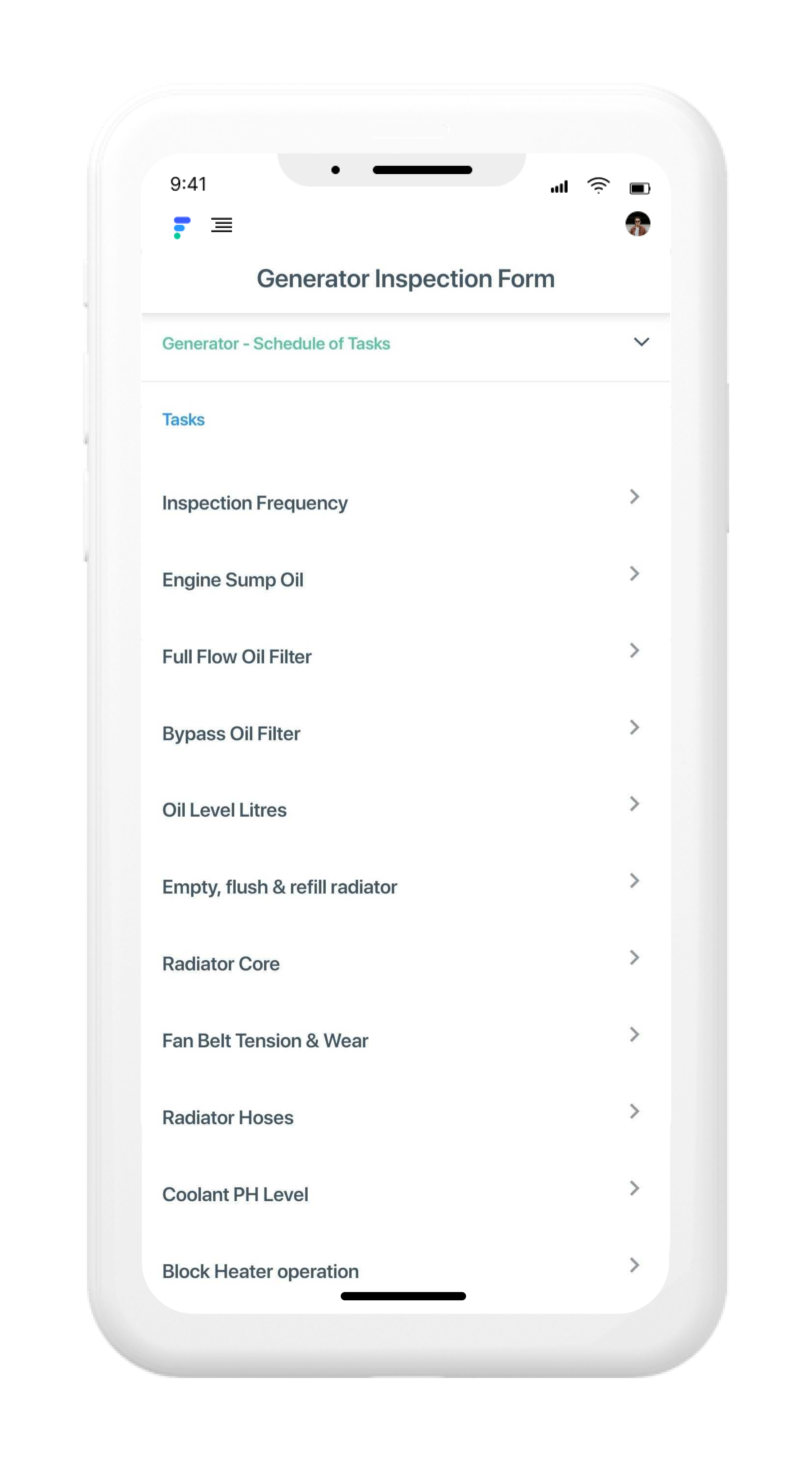

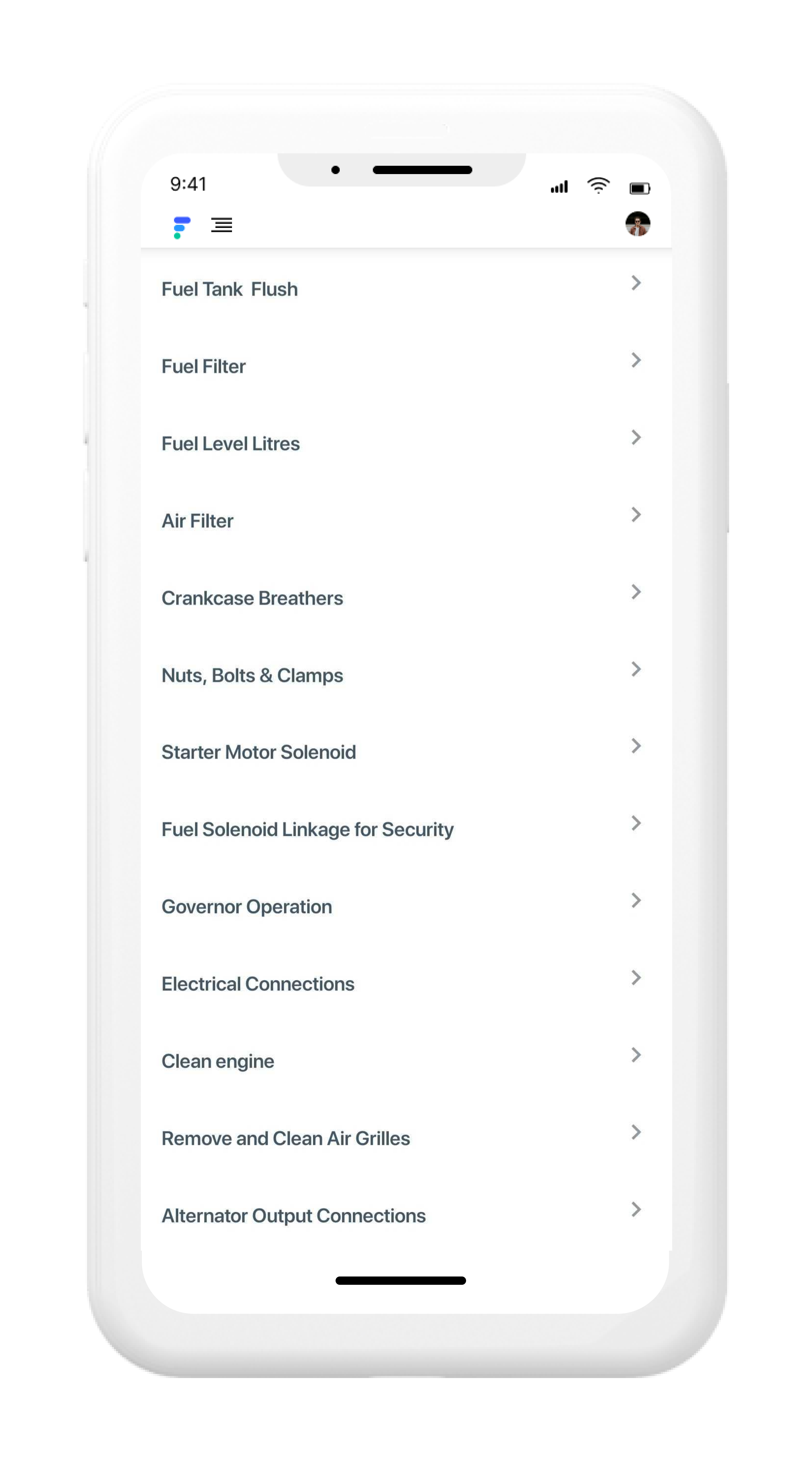

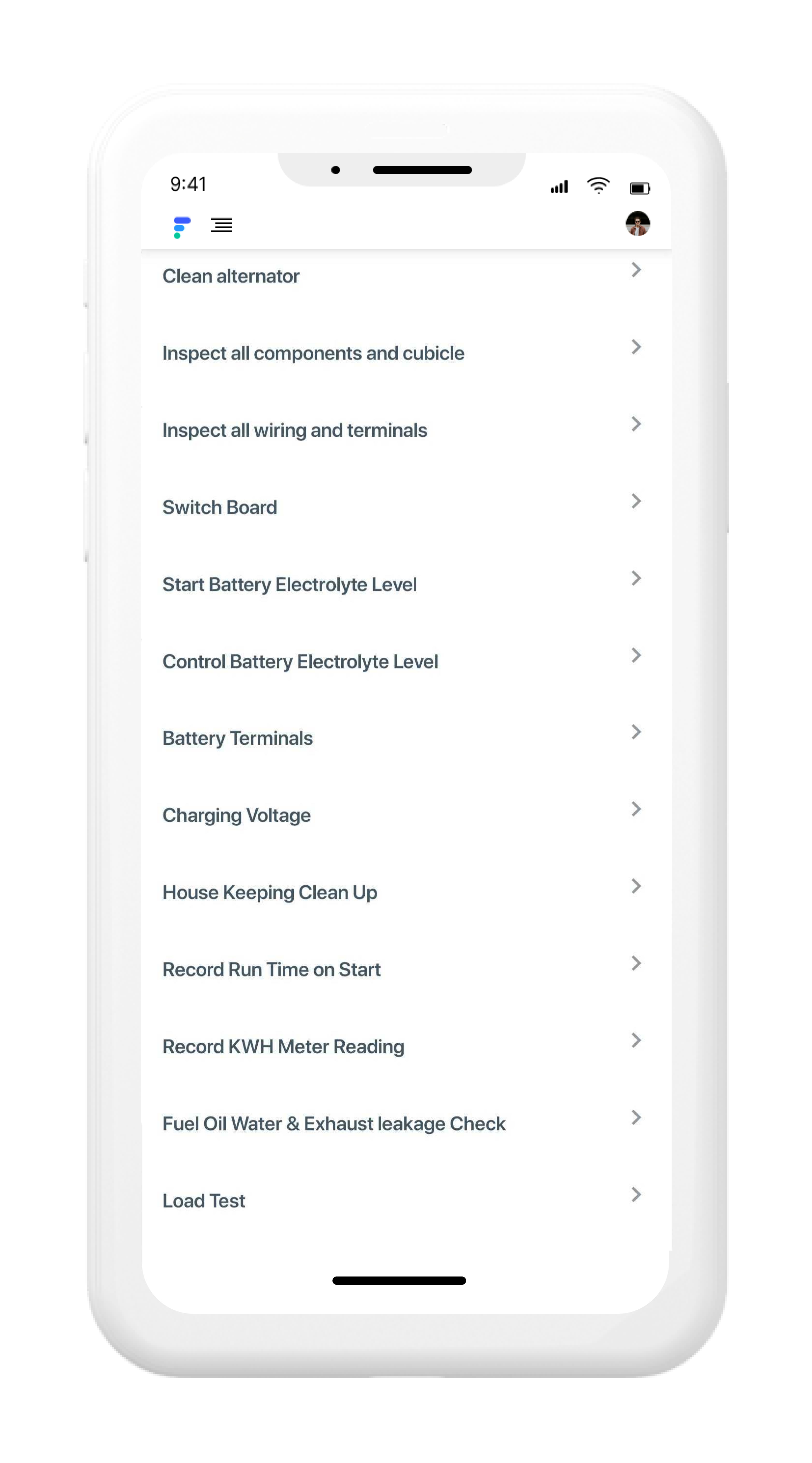

What is the purpose of Generator Inspection Checklist: When inspectors conduct routine checks on generators, they use Generator Inspection Checklists as a reference for the inspection process and to document observations. During visual inspections, they review the condition of controls, check for leaks, and inspect the wiring. They contain items like the lubricating oil level and viscosity, the state of air filters, fuel filter, fan belt, coolant level, fuel tank vents, exhaust system, etc. They also test battery charging, inspect the generator brush holders and brushes, check the coolant system for possible leaks, and clean the exciters.

What makes Generator Inspection Checklists vital: The frequency of inspections depends on the scale and criticality of operations. Companies may conduct inspections weekly, twice a week, or even daily. These inspections help ensure the generator is in optimum working condition. They help spot issues and fix them in time. These inspections also identify part replacements needed and spot potential problems in the emergent stage before they cause significant repairs and disruptions. As a result, companies keep generator costs down and retain their fuel efficiency, power quality, and reliability by ensuring timely issue maintenance.

How Fielda helps inspectors manage these checklists: Maintenance staff capture details from visual and operational inspections and document repairs, previous repairs conducted, part replacement required, etc. Traditional paper and pen data collection can be tedious. Fielda makes the process an easy and efficient all-mobile experience. Inspectors can create and modify generator inspection checklists as they see fit and complete the documentation in just a few easy clicks. They can also capture evidence such as videos and photos of leaks and damaged parts and upload them along with the checklist to enable service teams to take appropriate action.

Enhance Data Gathering: Improve the comprehensiveness, speed, and ease of field data collection with digital generator inspection checklists.

Consolidate and Collaborate: Share vital information across service teams for effective maintenance and repairs

Master Metrics: Consolidate Generator Inspection Checklist data from various sites and timeframes for cumulative metrics and reports

About Fielda: Fielda helps companies manage and maintain their assets and gain real-time oversight of all tasks, workflows, and projects to improve operational efficiency, enhance team productivity and impact the bottom line. Whether it’s installations, inspections, repairs, replacement of parts, servicing and maintenance, or routine audits, with Fielda’s mobile data collection, GIS-enabled technology, automated and custom workflows, and analytics, you can eliminate errors, enhance response time, ease workflow bottlenecks, and simplify your field operations.