Electrical panels are boxes that contain circuit breakers. These circuit breakers are designed to cut electrical current when it exceeds the safe supply level in a particular section of a unit’s electrical system. Therefore, regular electrical panel inspections ensure optimum condition and safety. Here we will discuss some highlights of electrical panel inspection:

- What do technicians look for during electrical panel inspection?

- What makes these inspections crucial to efficiency and safety in an electrical system?

- How does Fielda help staff conduct these electrical panel inspections with greater ease?

Elements of electrical panel inspection: During inspections, technicians check fundamental hygiene factors such as the condition of the panel, the minimum clearance around it, and the height of the working area. These are stipulated by regulatory bodies to ensure safety and must be strictly followed. Inspectors audit the equipment to check for damage by rodents, rust, corrosion, sharp-tipped screws, which could damage wiring, burnt components, etc. They also inspect wiring to ensure it is correctly done and check for water or moisture in the panel, which can corrode the circuit breakers and prevent them from functioning correctly.

Why electrical panel inspections are necessary: A poorly maintained electrical panel has several implications. For one, the panel and the circuit breakers inside can pose severe risks to electricians who work with these types of equipment. These electrical panel inspections are vital because they ensure the circuit breakers are functioning optimally. This prevents overload, which can cause accidents, damage equipment using the power within a particular system, and burn the components within the circuit breakers. Such damage can result in injuries or even death and significantly increase maintenance and repair costs.

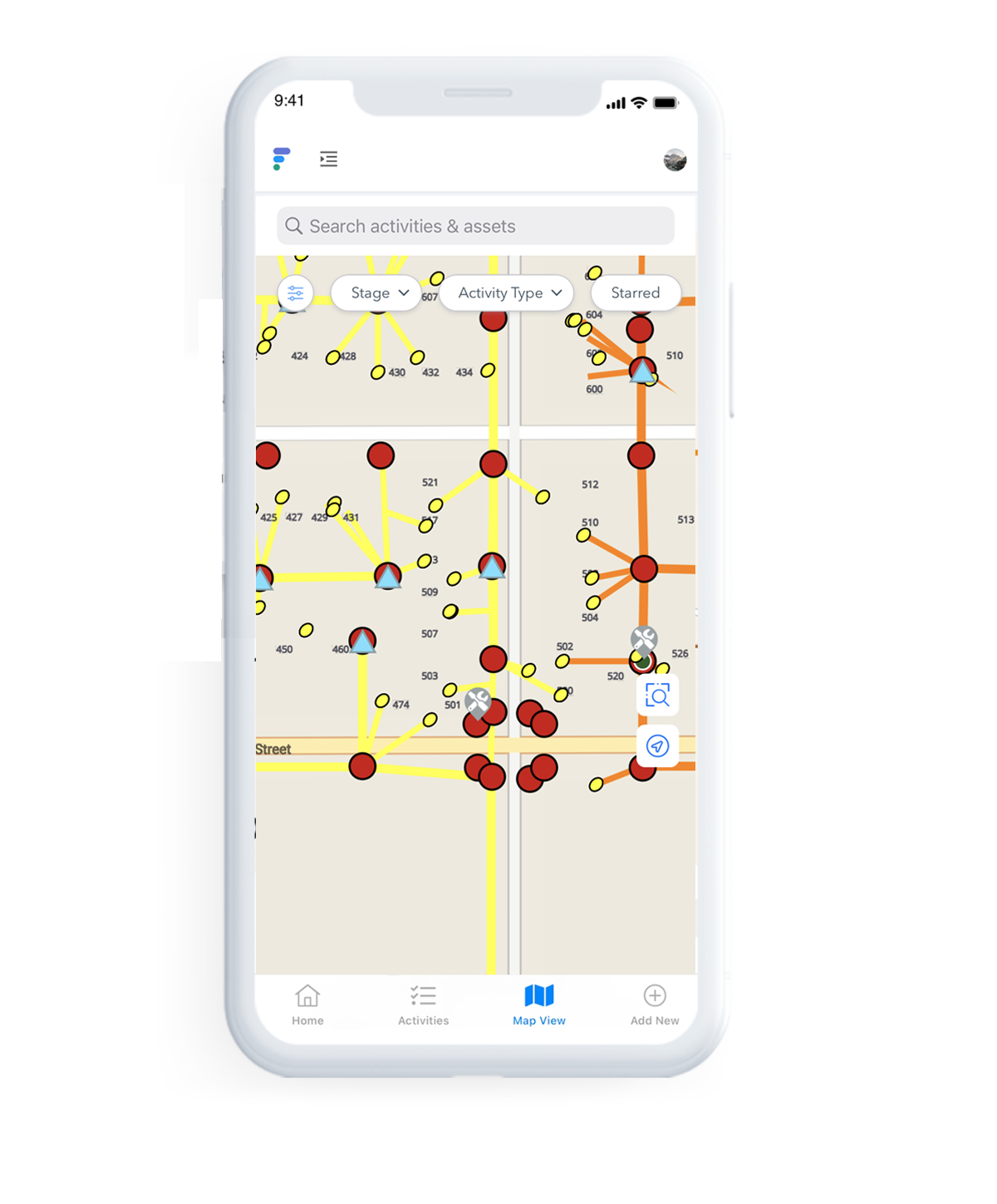

How Fielda helps technicians conduct electrical panel inspection more efficiently: Inspectors make several observations regarding the components in an electrical panel, its installation, and maintenance records. These often include additional notes about potential risks with specific electrical panels because of their location, position, or condition. Photographic and video evidence are also part of the records they gather and submit for repairs and services needed. Fielda streamlines this process. Its digital forms make data gathering flexible and easy operation, allowing for fields and additional note changes. In addition, inspectors can capture photos and submit them at one go from their mobile devices, making the inspection process seamless.

Inspect: Conduct electrical panel inspections in a fraction of the time required for manual data gathering.

Inform: Improve turnaround time by instantly sharing updates for service and repair teams to respond rapidly.

Leverage: Gain insights from Fielda’s real-time dashboards and metrics for informed decision-making.

About Fielda: Fielda helps companies manage and maintain their assets and gain real-time oversight of all tasks, workflows, and projects to improve operational efficiency, enhance team productivity and impact the bottom line. Whether it’s installations, inspections, repairs, replacement of parts, servicing and maintenance, or routine audits, with Fielda’s mobile data collection, GIS-enabled technology, automated and custom workflows, and analytics, you can eliminate errors, enhance response time, ease workflow bottlenecks, and simplify your field operations.